Advantages of Tubing compared to Pipe

Advantages of Tubing compared to Pipe

Imagine a system so simple that it could be assembled in half the time using just a few tools. One that reduces disassemble, retrofit and reassemble time by 75% while also eliminating exposure to flames, oils, metal shavings, weld gases and fumes.

What if this new system was also more reliable, had fewer leak points and reduced your overall install cost by up to 40%? What would that mean to your company?

Every day, you are challenged to do more - faster - and with less. Coupled with increased safety requirements, tighter budgets and stiffer competition, finding ways to simplify your systems is key.

Swagelok's tubing solutions offer simplicity, cost-effectiveness, and superior performance over pipe for many applications. Our tubing, fittings, and tools are designed to work together to ensure a reliable, leaktight, low-maintenance system. Plus, assembling tube fittings and bending tubing is often simpler, safer, faster and more reliable than installing welded or threaded pipe systems while saving on installation, operating, and maintenance costs.

Drawbacks to Pipe

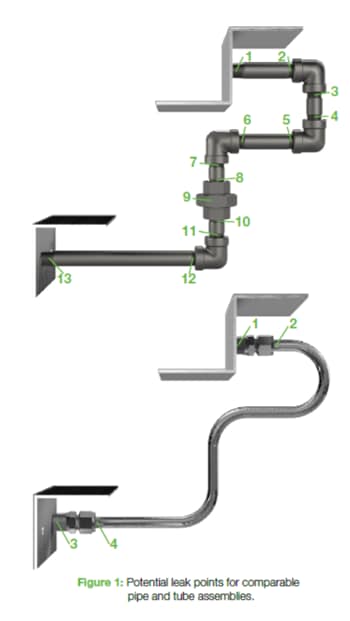

There are some inherent drawbacks to using pipe over tubing. To make up a desired run using pipe, it must be cut, deburred, and then threaded. All male threads must be wrapped with a PTFE tape or covered with a sealant. The pipe fittings are then tightened wrench tight. Additionally, the piping system has more potential leak points (Figure 1) than it would if tubing had been used.

Advantages of Tubing

Now let’s look at the same system made with tubing. As with pipe, the tubing must be cut and deburred. However, the tubing simply needs to be bent - no extra fittings are required. Plus, a tubing bend creates less turbulence and pressure drop than a pipe elbow.

What about strength? Pipe is heavier and has a thicker wall, but a thick wall is not needed to contain system pressure. That extra material is there so that it can be cut away to create the threads. The additional weight from pipe means additional transportation and handling costs as there is more weight to store, lift and install. Plus, a heavier system puts greater strain on the supports. Tubing, on the other hand, is sealed on its outside diameter. The wall thickness is used primarily for safe pressure containment, providing an improved strength-to-weight ratio.

Why Choose Swagelok Tubing?

Swagelok's tubing solutions offers:

- Ease of Installation: Only simple tools are needed to install Swagelok tube fittings. No threading, flaring, soldering, or welding is required.

- Lower Pressure Drop: Sharp bends and transitions of piping systems are not present in the gradual bends and smooth ID of a tubed system.

- Fewer Connections Needed: Bending reduces the number of necessary connections and potential leak points. Tubing is adaptable and can easily be bent around obstructions.

- Better Strength to Weight Ratio: The full wall thickness of tubing is pressure containing, whereas the wall of pipe is used for threading. The lighter weight of the tubing provides many benefits in that it costs less to transport, is easier to assemble, requires fewer supports when hanging, and physically occupies less space.

- Leak-Tight Seal: At high pressures or temperatures, pipe connections often leak! Tubing systems connected with Swagelok tube fittings are leak tight without using additional sealing compounds. Compressed air, steam, hydrogen, helium, and hydraulic oil all add to the operating cost of a plant. An inadequate connection that leaks can far exceed the cost of a more expensive Swagelok tube fitting that provides positive performance.

- Easy Maintenance: Every Swagelok tube fitting acts as a union. When disassembly is needed, it is a simple and safe process. This, coupled with a leak tight seal, translates to easy maintenance. There is no need to disconnect a series of pipe lengths and fittings to remove an individual component from the system.

Need more Information or looking for a specific product?

Just fill in the below form and we will come back at the earliest<