Fitting attachment methods of Hose end connections

Fitting attachment methods of hose end connections

The performance of a hose assembly depends largely on the ability to properly attach the end connection. The point where the hose end connection attaches to the hose can create stress and is typically where most hose leaks occur. The type of end connection is typically dictated by the hose selected and the requirements of the application. In some cases, a hose may be identified by the attachment method. For example, an end connection that has been welded to the hose likely has a metal core tube. An end connection that has been crimped or swaged to the hose likely has a fluropolymer or other non- metal core tube.

Welded

Metal hoses come with a variety of end-connection choices. With metal hoses, the connections are welded to completely and permanently seal the connection to the hose assembly. Swagelok Hose Series – FJ, FL and FM. Each of these series have all metal core tubes and wire reinforcement. Convoluted tubing also uses this method.

Crimped or Swaged onto the Hose

For fluoropolymer hoses, you must select between swaging and crimping. Swaging puts pressure on the hose itself, while crimping squeezes the end connection. Both methods are widely accepted but crimping has a slight advantage in that it's less likely to damage the hose because the pressure is exerted in a carefully controlled manner.

Swagelok Hose Series – B, C, F, N, X, S, U, W. All these series have a fluropolymer core tube. The type and number of reinforcement layers differ by series.

Swagelok Hose Series – 7P, 7R, 7N, 8R, 8N, T. All these series have a thermoplastic core tube. The 7P is polyethylene.

Flare-through

Many chemical applications require use of fluoropolymers on wetted end connections. The hose industry has devised some creative solutions. One is “flare-through" — the fluoropolymer core tube is flared such that it covers the entire inner surface of the metal end connection. This avoids a step or drop between the core tube and fitting, ensuring smooth flow. However, flare-through is fragile and not recommended for high temperature applications.

Encapsulation

Another common and lower-cost solution is called “encapsulation" - fluoropolymer entirely encapsulates the stainless-steel end connection, inside and out. This allows for a corrosion resistant end connection. However, this reduces orifice size, raising the possibility of decreased flow and entrapment.

Other, less common end connection methods include clamped, screwed and pushon.

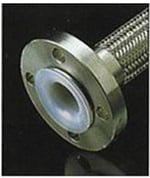

Different Hose End Connections

Need more Information or looking for a specific hose/advisory service?

Just fill in the below form and we will come back at the earliest