Prevent creep in regulators

Creep in Regulators - Cause, Effect and Prevention

Creep occurs when the poppet is in the closed position, yet the seat allows pressure to escape to the outlet side. If the poppet does not fully seat in the orifice, inlet pressure may continue to bleed through the orifice. Over time this leakage can increase the outlet pressure until it equals the inlet pressure (Figure 1).

Causes of Creep

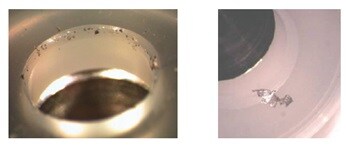

- Contamination of the seat (Picture 1)

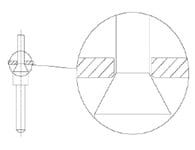

- Damage to the poppet or seat

- Misalignment of the poppet to the seat (Picture 2)

Picture 1 Picture 2

Creep generally occurs because the seat may have been damaged or eroded. For instance, regulator seats can be compromised by particulates in the process stream, which can cause minor imperfections in the sealing surface. The high flow and small orifice that is created during the regulation of pressure combine to turn a very small particle into a very fast projectile. As such, these small particles can nick the surface of the seat and cause leakage of pressure from the high-pressure inlet to the low-pressure outlet.

Effect of Creep

- If not controlled, overpressure due to creep may cause damage to the regulator, such as diaphragm rupture.

- Pressure sensitive equipment downstream of the regulator may be damaged when the over pressure condition is released.

Prevent Creep

- Filter the fluid to minimize damage

- Do not use regulator as a shutoff device

- Relief valve to protect downstream equipment incase of failure due to creep

- ALWAYS buy a replacement kit

Need more Information or looking for a specific regulator?

Just fill in the below form and we will come back at the earliest