Advantages of using Swagelok Snoop® Liquid Leak Detector

Advantages of using Swagelok Snoop® Liquid Leak Detector

There are a few ways to find gaseous leakage. One option is to immerse the parts in water to see if the leak can be seen, however this is not always feasible, especially when working with installed systems and/or components. Another method is to use soap water on potential leak point. When you see bubbles, you know you have a leak if the leak is big enough.

Alternatively, you can use Swagelok snoop solution. Snoop is made of deionized water and a special surfactant. It reveals small leaks and low-velocity leaks that soapy water won't reveal. The key difference between Snoop and regular soap water is that the former will continue to produce bubbles for a short while after application, whereas the latter may just provide you with one set of bubbles to see before dissolving.

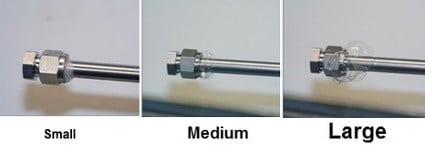

The bigger the leak, the bigger the bubbles.

Features

■ Sustained bubble action works even on very small leaks and vertical surfaces.

■ Flexible snooper tube extends for hard-to-reach areas.

■ Noncorrosive, non-flammable formula does not contain chlorine.

■ Contains corrosion inhibitor for added protection.

■ Formula dries clean, without staining

Temperature rating: Can be used over a temperature range of 27 to 200°F (–2 to 93°C).

Specifications: Meets the performance requirements of:

■ MIL-PRF-25567 Leak Detector Compound, Oxygen Systems, Type I, 1 to 70°C (33 to 158°F).

■ NFPA 52 Section 6-12.2 Leak Testing Compressed Natural Gas Vehicular Fuel System.

■ EPA Part 60, Appendix A, Method 21, Section 4.3.3 Alternative Screening Procedures Using Soap Solutions.

■ ASTM G186-05, Standard Test Method for Determining Whether Gas-Leak-Detector Fluid Solutions Can Cause Stress Corrosion Cracking of Brass Alloys.

You can use Real Cool Snoop – for leak detection over a temperature range of –65 to 200°F (–54 to 93°C).