Compressed Natural Gas (CNG), Natural Gas Vehicles (NGV)

Swagelok Bangalore is highly active in the compressed natural gas market across India. We supply Swagelok products to light duty and heavy duty natural gas vehicles (NGV) and CNG station (City Gas Distribution - CGD) applications across India. Furthermore, our products can be currently found in fuel lines in some of the India's leading CNG vehicle manufacturers.

We offer Swagelok Tube Fittings, AbT Fittings, Alternative Fuel Service (AFS) Ball Valves, 83 Series High-Pressure Ball Valves, 83 DXL 3 Way Ball Valve, 4SK Series Ball Valve, L83P, L83XP Series 2 & 3 Way Ball Valve, 4P Series Purge Valve, CH Series Check Valve, BV Series Bleed Valve, 8R Series Hose, 8R Series Hose, NG Series Hose, Swagelok TF Series Filter, PGN Series Guage, Bend Tube Assemblies, custom built assemblies, Priority Panels and more.

What our customers say about us

'We have been using Swagelok fittings and valves for CNG vehicles. We are extremely satisfied with the Swagelok product quality and services.' - Large automobile manufacturing company in India

'We appreciate Swagelok Delhi's commitment to quality and service. We look forward for same support all new technologies of Swagelok products in future as well'. - Large gas distribution company in India

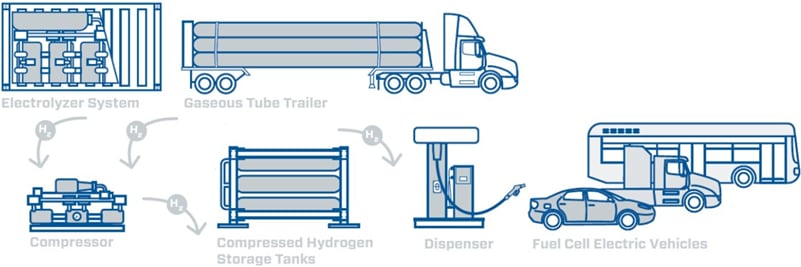

CNG Infrastructure

CNG is a dangerous fuel due to a combination of the high pressure under which it is stored and its flammable nature. Safety is of utmost importance and an accident can result in serious consequences. It is hence very important that a gas distribution company gives due importance to the selection of products for all CNG station related applications like cascades, compressors, priority panels, dispensers, station forecourt areas etc.

Swagelok Bangalore has been servicing this market in India since inception and we provide products, assemblies and services to all major City Gas Distribution companies across India.

Swagelok offers Tube Fittings, Valves, Hoses, Tubing, Filters, Pressure Guages, Tools & accessories and Pressure Regulators. Several of our products also meet or exceed compliances like AGA, CGA, CSA, ECE, ISO, NGV, and PED to name a few. In addition to the products, we also offer a host of services such as Custom Solutions (We build Priority Panels, Hose Assemblies, Valve assemblies), Swagelok Certified Training, Energy Audits, Vendor Managed Inventory, Application Support and Compressed Gas Leak Detection Services.

Natural Gas Vehicles

Swagelok Bangalore is highly active in the Natural Gas Vehicle market across India since its inception. Swagelok products can be currently found in fuel lines in some of the India's leading CNG vehicle manufacturers. As the market continues to grow, Swagelok offers you more than ever. We have developed Assembly by Torque fittings especially for this market. Several of our products also meet or exceed compliance and standard measures including AGA, CGA, CSA, ECE, ISO, NGV, and PED to name a few.

In addition to offering highest quality Swagelok products such as Fittings, AFS ball valves, Check valves, Needle valves, Metering valves, 83 series ball valves, pressure Gauges, Snoop leak detectors, Hand tube benders, High volume swaging units; we also support our customers with Training Services, Local stock in our ware houses in Gurgaon and Bangalore, Onsite support, Assembly services, Application Support and more.